Features of the Pipe-to-Pipe Automatic Welding Equipment

Date: 2025-11-12 Categories: Case Hits: 312

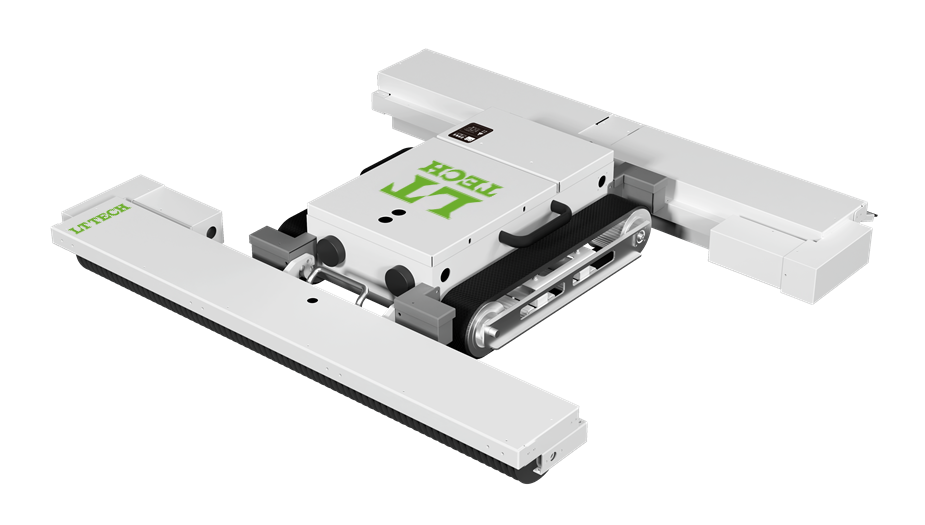

Features of the Pipe-to-Pipe Automatic Welding Equipment

1. The welding process is fully automated, achieving high automation levels and welding efficiency.

2. Utilizes a slip ring structure integrating wire feed, compressed air, and welding gas pathways, enabling unlimited rotation of the welding head without tangling.

3. Automatic alignment via positioning fixtures compensates for pipe inclinations up to 3 degrees.

4. Color touchscreen HMI provides an intuitive, user-friendly interface. Segmented welding parameter settings are configurable on the touchscreen. Stores 20 welding specifications, enabling setup, recall, modification, and storage directly via the touchscreen.

5. Automatic return position for the welding torch is achievable. Each welding cycle completes a full rotation with a specified overlap angle. Cable entanglement does not occur during welding.

6. After pneumatic clamping, manual support is unnecessary during operation, allowing one operator to simultaneously manage multiple welders.

7. Compact size, flexible operation, and simple maintenance.

8. Compatible with 20KG spool welding wire, eliminating frequent wire changes.

KA-H1 Standard Corner Welding...

KA-H1 Standard Corner Welding...  KA-H4 Double-sided Corner Weld...

KA-H4 Double-sided Corner Weld...  KA-H5 Side-Suction Corner Weld...

KA-H5 Side-Suction Corner Weld...  KA-C1 Track-type Welding Tract...

KA-C1 Track-type Welding Tract...  KA-HE8Pro Track-type Oscillati...

KA-HE8Pro Track-type Oscillati...  KA-150 All-Position Pipe Welde...

KA-150 All-Position Pipe Welde...  GT Series Welding Gun

GT Series Welding Gun  GTW200 Welding Power Source

GTW200 Welding Power Source  SC-Lite

SC-Lite  LS-Standard

LS-Standard  FR10 Mobile Welding Robot

FR10 Mobile Welding Robot