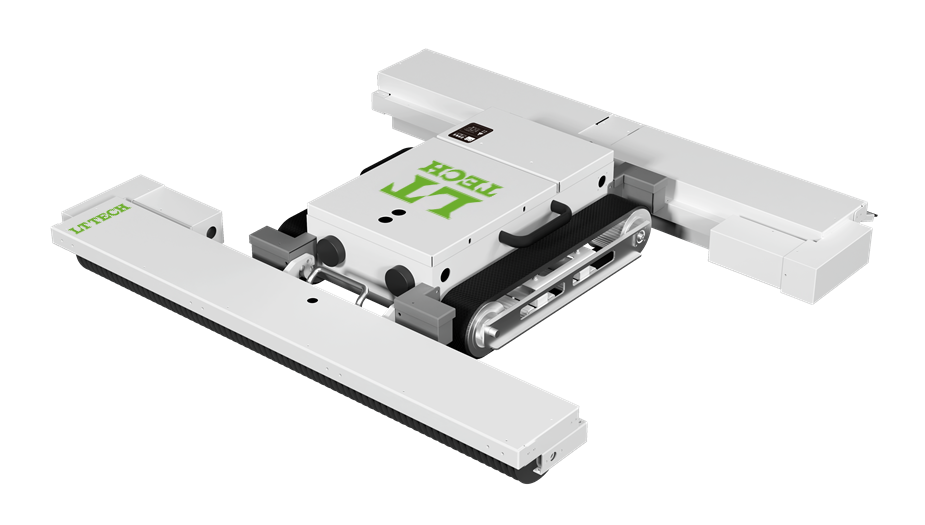

KA-150 All-Position Pipe Welder

The system achieves fully automatic pipeline welding in all positions (5G welding) by securing pipes and utilizing a welding cart for movement. The welding process employs highly efficient, low-cost CO₂ gas or mixed gas shielding (80% argon + 20% CO₂).

Advantages of All-Position Pipe Welding: Wireless remote control allows pre-programmed settings or real-time parameter adjustment via the controller, with stored parameters accessible for future use. The system automatically identifies welding positions through built-in orientation sensors, recognizing angles between 1 o'clock and 12 o'clock. It dynamically adjusts current, voltage, and travel/oscillation parameters to match specific positions. Simple operation.

1. Applicable Conditions: Field welds for various long-distance pipelines, thermal pipelines, buried pipelines, or process pipelines.

2. Weldable Materials: Carbon steel, stainless steel, alloy steel, low-temperature steel, etc.

3. Applicable Welds: Suitable for pipes with diameters ≥Φ150mm and wall thicknesses >5mm. Multi-layer, multi-pass welding can be used for thick-walled pipes.

4. Welding Cart: Compact and portable design with permanent magnet attachment, ideal for all-position pipeline welding at construction sites.

5. Wireless Remote Control: Pre-set welding parameters via wireless remote; real-time fine-tuning during operation based on conditions. Simple operation with low labor intensity.

6. Welding Efficiency: High speed and productivity, achieving approximately 3-4 times the output compared to manual arc welding.

KA-H1 Standard Corner Welding...

KA-H1 Standard Corner Welding...  KA-H4 Double-sided Corner Weld...

KA-H4 Double-sided Corner Weld...  KA-H5 Side-Suction Corner Weld...

KA-H5 Side-Suction Corner Weld...  KA-C1 Track-type Welding Tract...

KA-C1 Track-type Welding Tract...  KA-HE8Pro Track-type Oscillati...

KA-HE8Pro Track-type Oscillati...  KA-150 All-Position Pipe Welde...

KA-150 All-Position Pipe Welde...  GT Series Welding Gun

GT Series Welding Gun  GTW200 Welding Power Source

GTW200 Welding Power Source  SC-Lite

SC-Lite  LS-Standard

LS-Standard