What should be noted during automatic pipe-to-pipe welding?

Date: 2025-11-12 Categories: Case Hits: 260

What should be noted during automatic pipe-to-pipe welding?

1. If wire feeding becomes unstable during automatic pipe welding, stop immediately and resume only after troubleshooting;

2. Keep the welding gun cable taut during automatic pipe welding and promptly untangle any kinks;

3. Strengthen welder responsibility training: halt welding immediately upon detecting issues and address them promptly. Consult experienced personnel if uncertain;

4. Ensure grounding cables maintain good contact;

5. Install wind protection shelters for automatic pipe welding and implement windproof measures;

6. Verify generator network voltage remains within normal range;

7. Keep the welding machine's air duct unobstructed;

8. Continuously inspect shielding gas lines and gas gauges for leaks;

9. After daily welding operations, thoroughly clean spatter, iron filings, and dust from the welding cart and wire feeder;

10. Each windshield shelter must be equipped with an air compressor to clean iron filings and dust from welding equipment and the shelter interior, providing welders with a clean working environment;

11. Before moving to the next weld joint, disconnect the welder's power supply;

12. Untrained welders are prohibited from operating equipment;

13. Non-professionals are strictly forbidden from opening housings for welding equipment maintenance.

The automated pipe welding process involves the integration and interaction of multiple factors, including understanding welding materials, adjusting current and voltage, regulating welding speed, controlling gas flow, positioning the torch angle, and managing weld distortion. For instance, the coordination of welding current/voltage adjustments with welding speed requires extensive experience. During machine debugging, this coordination enables rapid adjustments, minimizing material waste.

KA-H1 Standard Corner Welding...

KA-H1 Standard Corner Welding...  KA-H4 Double-sided Corner Weld...

KA-H4 Double-sided Corner Weld...  KA-H5 Side-Suction Corner Weld...

KA-H5 Side-Suction Corner Weld...  KA-C1 Track-type Welding Tract...

KA-C1 Track-type Welding Tract...  KA-HE8Pro Track-type Oscillati...

KA-HE8Pro Track-type Oscillati...  KA-150 All-Position Pipe Welde...

KA-150 All-Position Pipe Welde...  GT Series Welding Gun

GT Series Welding Gun  GTW200 Welding Power Source

GTW200 Welding Power Source  SC-Lite

SC-Lite  LS-Standard

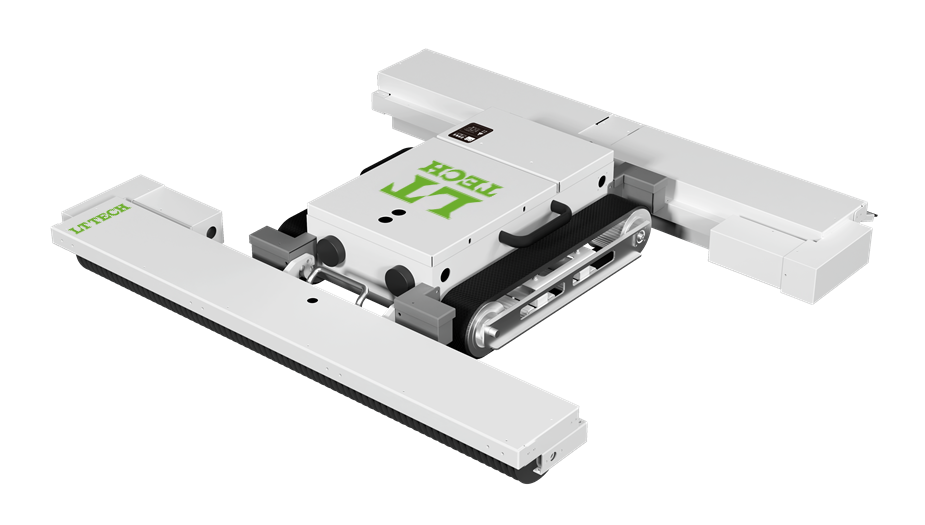

LS-Standard  FR10 Mobile Welding Robot

FR10 Mobile Welding Robot