What should be considered when selecting a tube-to-tube welding machine?

Date: 2025-11-12 Categories: Industry News Hits: 254

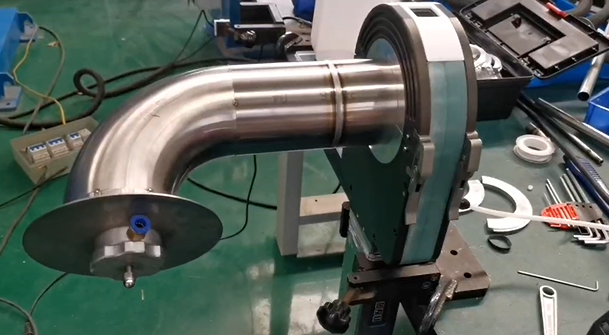

Tube-to-tube welding machines are specialized welding devices, with only a handful of manufacturers globally producing them. Currently, these machines are used for welding metals such as stainless steel, carbon steel, and titanium alloys with wall thicknesses under 3mm, as well as copper pipes under 2mm. A single welding power source is typically universal for these materials. The differences lie in the welding guns and dies, with different die sets required for varying pipe diameters.

When selecting equipment, focus on these key points:

- Assess the wall thickness and diameter of the pipes you need to weld to determine how many torches and mold sets are required.

- Review the equipment's specifications, performance, component origins, and manufacturing location to ensure it comes from a reputable supplier capable of providing technical support and after-sales service.

- Investigate the equipment's welding pass rate.

- Compare equipment prices.

KA-H1 Standard Corner Welding...

KA-H1 Standard Corner Welding...  KA-H4 Double-sided Corner Weld...

KA-H4 Double-sided Corner Weld...  KA-H5 Side-Suction Corner Weld...

KA-H5 Side-Suction Corner Weld...  KA-C1 Track-type Welding Tract...

KA-C1 Track-type Welding Tract...  KA-HE8Pro Track-type Oscillati...

KA-HE8Pro Track-type Oscillati...  KA-150 All-Position Pipe Welde...

KA-150 All-Position Pipe Welde...  GT Series Welding Gun

GT Series Welding Gun  GTW200 Welding Power Source

GTW200 Welding Power Source  SC-Lite

SC-Lite  LS-Standard

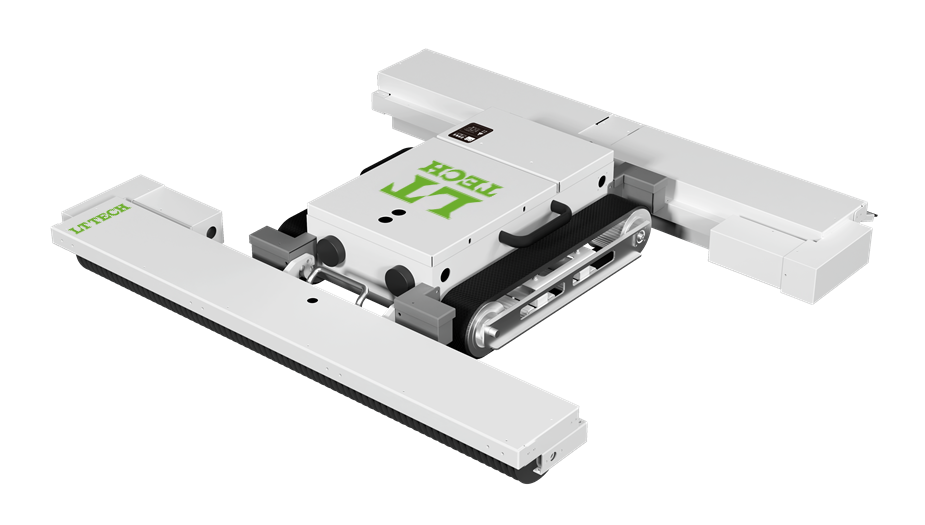

LS-Standard  FR10 Mobile Welding Robot

FR10 Mobile Welding Robot