What are the advantages of automated pipe welding?

Date: 2025-11-12 Categories: Industry News Hits: 359

What are the advantages of automated pipe welding?

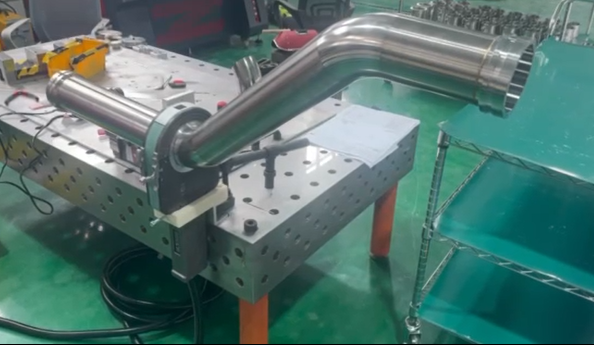

1. The use of dual-torch external welding machines for filler application combined with narrow-gap grooves significantly reduces welding time. This results in over 50% savings in filler material and a 50% reduction in welding time.

2. Under normal conditions, a fully automated unit can complete approximately 35-50 pipe welds per day, achieving 3-4 times the productivity of semi-automatic welding.

3. Welding parameters can be remotely monitored in real time. The process ensures stable parameters, high welding speed, superior weld quality, low dispersion in weld mechanical properties, and consistent quality.

KA-H1 Standard Corner Welding...

KA-H1 Standard Corner Welding...  KA-H4 Double-sided Corner Weld...

KA-H4 Double-sided Corner Weld...  KA-H5 Side-Suction Corner Weld...

KA-H5 Side-Suction Corner Weld...  KA-C1 Track-type Welding Tract...

KA-C1 Track-type Welding Tract...  KA-HE8Pro Track-type Oscillati...

KA-HE8Pro Track-type Oscillati...  KA-150 All-Position Pipe Welde...

KA-150 All-Position Pipe Welde...  GT Series Welding Gun

GT Series Welding Gun  GTW200 Welding Power Source

GTW200 Welding Power Source  SC-Lite

SC-Lite  LS-Standard

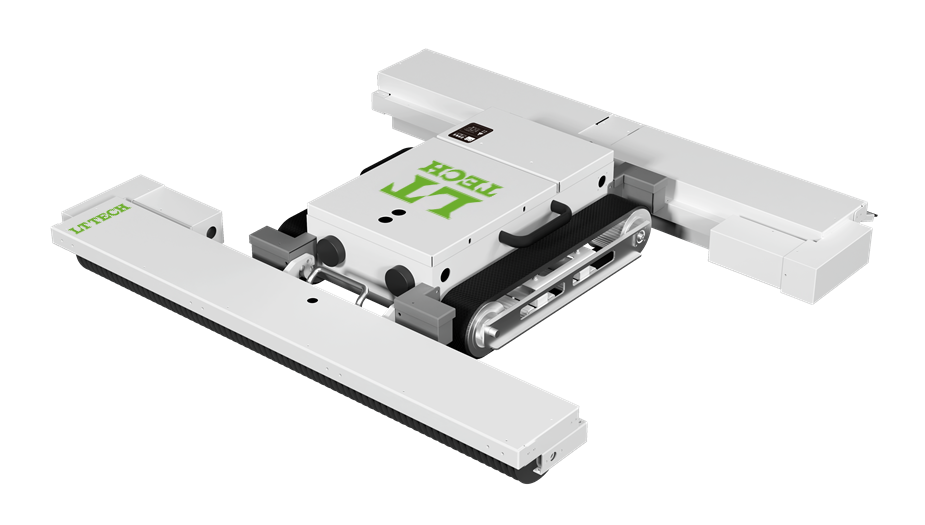

LS-Standard  FR10 Mobile Welding Robot

FR10 Mobile Welding Robot