Cost Comparison Analysis Between Pipeline Welding Carts and Traditional Welding Processes!

Date: 2025-11-12 Categories: Industry News Hits: 339

In pipeline construction projects, the choice of welding process directly impacts project costs. Traditional manual welding relies on welder experience, while pipeline welding carts revolutionize production models through automation technology. Significant cost differences exist between the two in terms of equipment investment, labor consumption, and quality maintenance. This article will conduct an in-depth comparison across multiple dimensions.

1. Equipment Investment Costs: Balancing Short-Term Expenditures and Long-Term Benefits

Traditional welding equipment primarily consists of basic tools like welding machines, clamps, and face shields, with initial procurement costs typically ranging from several thousand to tens of thousands of yuan, appearing relatively low-threshold. However, such equipment is prone to wear and tear, requiring frequent replacement of consumables like electrode holders

and cables require frequent replacement, resulting in substantial long-term maintenance and upgrade expenses. In contrast, pipeline welding carts, as automated equipment, carry initial purchase costs ranging from ¥100,000 to ¥500,000, representing a relatively higher investment. However, their modular design ensures core components last 5-8 years with minimal maintenance—requiring only periodic track wear and sensor accuracy checks. Over the long term, this yields a more advantageous total lifecycle cost. For instance, in a medium-sized pipeline project, traditional welding equipment incurred over 80,000 yuan in replacement costs due to aging within three years, while the welding cart's maintenance expenses during the same period were less than 20,000 yuan.

2. Labor Costs: Transitioning from Labor-Intensive to Efficient Operations

Traditional manual welding is labor-intensive, requiring numerous welders and support personnel. For a 1-meter diameter pipe weld, each joint requires 2-3 welders working in shifts. At an average daily wage of ¥500 per worker, completing 100 joints incurs labor costs of ¥100,000–150,000. Additionally, welder training cycles are lengthy and technical training expenses are high. Welding carts significantly reduce labor dependency, requiring only 1-2 operators per unit who can be trained for operation in a short period. For the same 100 welds, a welding cart can complete the task within 3 days, reducing labor costs to just 30,000-60,000 yuan—a 60%-80% decrease. A natural gas pipeline project that adopted welding carts reduced its welder count from 80 to 20, achieving annual labor cost savings exceeding 3 million yuan.

3. Material and Quality Costs: Precision Control vs. Waste Variation

In traditional welding, operator skill variations often lead to electrode waste and defects. Statistics show manual welding achieves only 70%-80% electrode utilization, with rework rates as high as 15%-20% due to uneven welds, porosity, and other issues. The pipeline welding cart, equipped with an automatic wire feeding system and intelligent parameter control, boosts electrode utilization to over 95% while keeping defect rates below 5%. For a 1,000-ton pipeline welding project, traditional methods incur approximately 400,000 yuan in additional costs from material waste and rework, whereas the welding cart incurs only 100,000 yuan—a 75% savings. Additionally, the uniform welds produced by the welding cart reduce post-welding repair costs for anti-corrosion coatings, further lowering overall expenses.

4. Time Cost: Hidden Benefits from Compressed Project Duration

Traditional welding's low efficiency often results in prolonged project timelines for large-scale initiatives, generating significant hidden costs such as site rental, equipment downtime, and capital tied-up. Pipe welding trolleys, with welding speeds 3-5 times faster than manual labor, can significantly shorten project timelines. For instance, a cross-sea pipeline project reduced its schedule from 180 days to 120 days after adopting welding trolleys, saving 800,000 yuan in site rental costs alone. The economic benefits from earlier commissioning were even more substantial.

From long-term equipment amortization to optimized labor and material utilization, coupled with hidden gains from accelerated project timelines, pipeline welding carts demonstrate significant advantages in comprehensive cost control. Despite higher initial investment, their automation and precision are emerging as core solutions for cost reduction and efficiency enhancement in pipeline engineering.

KA-H1 Standard Corner Welding...

KA-H1 Standard Corner Welding...  KA-H4 Double-sided Corner Weld...

KA-H4 Double-sided Corner Weld...  KA-H5 Side-Suction Corner Weld...

KA-H5 Side-Suction Corner Weld...  KA-C1 Track-type Welding Tract...

KA-C1 Track-type Welding Tract...  KA-HE8Pro Track-type Oscillati...

KA-HE8Pro Track-type Oscillati...  KA-150 All-Position Pipe Welde...

KA-150 All-Position Pipe Welde...  GT Series Welding Gun

GT Series Welding Gun  GTW200 Welding Power Source

GTW200 Welding Power Source  SC-Lite

SC-Lite  LS-Standard

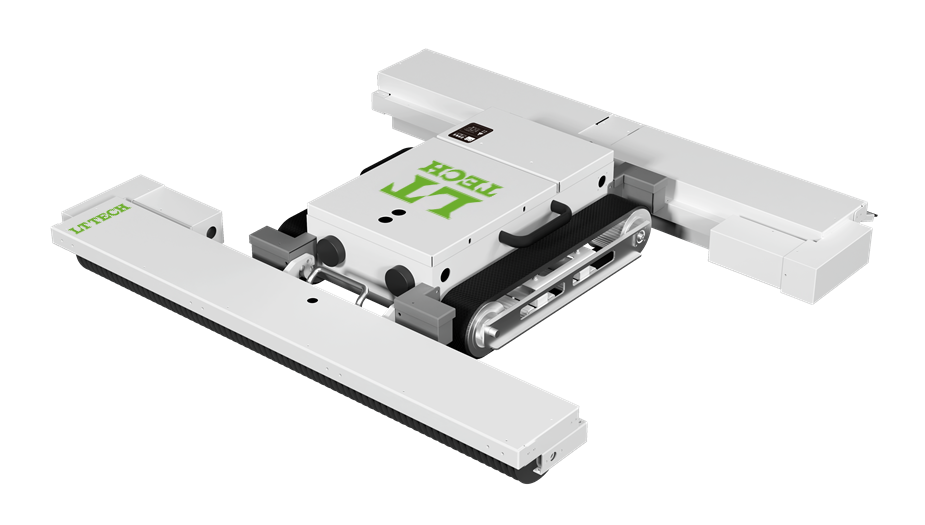

LS-Standard  FR10 Mobile Welding Robot

FR10 Mobile Welding Robot