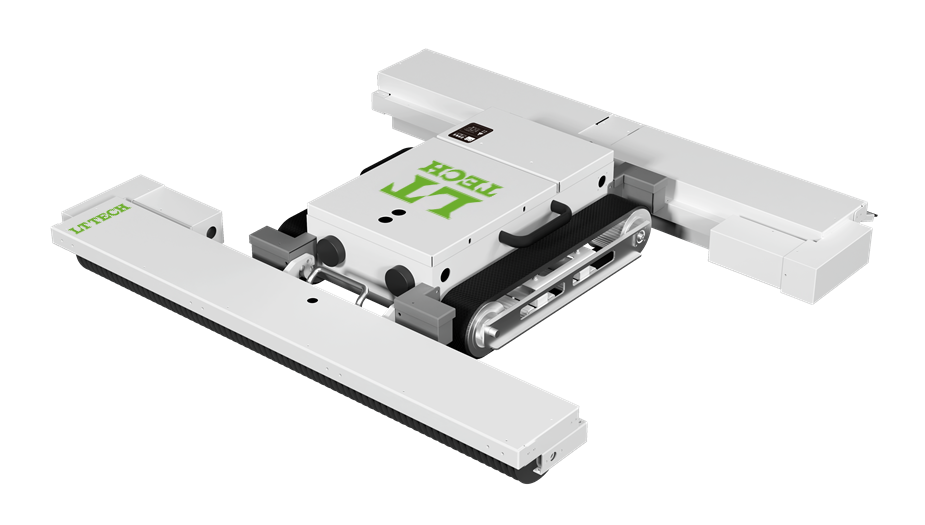

KA-H10 Flexible-Track Ring-Seam Welding Tractor

The KA-H10 is a welding equipment that travels along rails using a rack-and-pinion drive system. It is widely used for horizontal butt welding and vertical butt welding, particularly suited for medium-to-thick plate welding and large-diameter pipe circumferential welding. By adjusting the position and angle of the welding torch, it can also perform fillet welding, horizontal welding, overhead welding, and arc welding. The carriage body, swing mechanism, and control panel are separate units, enabling simultaneous travel and welding along the rails. The track is secured to the workpiece using powerful magnets, enabling easy installation and removal.

1) The KA-H10 enables multi-position welding, including vertical, horizontal, fillet, and circumferential welding.

2) Features linear oscillation functionality. Various oscillation parameters—including oscillation mode, amplitude, speed, center position, and left/right dwell time—are fully adjustable.

3) Digital display indicates carriage travel speed.

4) Equipped with left/right oscillation dwell time adjustment to prevent undercut and insufficient weld during oscillation welding.

5) Welding gun automatically returns to weld center position upon welding stop.

6) Features rapid return function.

7) Standard configuration includes 1.8m track. Compact and lightweight track facilitates easy movement and can be extended by connecting additional sections.

KA-H1 Standard Corner Welding...

KA-H1 Standard Corner Welding...  KA-H4 Double-sided Corner Weld...

KA-H4 Double-sided Corner Weld...  KA-H5 Side-Suction Corner Weld...

KA-H5 Side-Suction Corner Weld...  KA-C1 Track-type Welding Tract...

KA-C1 Track-type Welding Tract...  KA-HE8Pro Track-type Oscillati...

KA-HE8Pro Track-type Oscillati...  KA-150 All-Position Pipe Welde...

KA-150 All-Position Pipe Welde...  GT Series Welding Gun

GT Series Welding Gun  GTW200 Welding Power Source

GTW200 Welding Power Source  SC-Lite

SC-Lite  LS-Standard

LS-Standard